TIMELINE & PROCESS FOR SCREEN PRINTING JOBS

Frequently Asked Questions

1. You send us your artwork for review with relevant details about your job

2. We review your order details and help you choose the right garment

3. We’ll send you a written quote outlining the cost after we capture all of the information we need

4. You submit payment for your job to start your order

5. We send you a proof for approval – typically within 2 business days

6. You approve your proof and the production timeline starts. Your job is sent to production and we order your garments.

- Typical production times are 10 business days.

- Additional time is required to complete jobs with multiple decoration types, locations or finishing services.

7. We will notify by email when your order is ready for pickup or it is shipped to you.

- Please allow an additional 1-7 business days transit time for orders that are shipped.

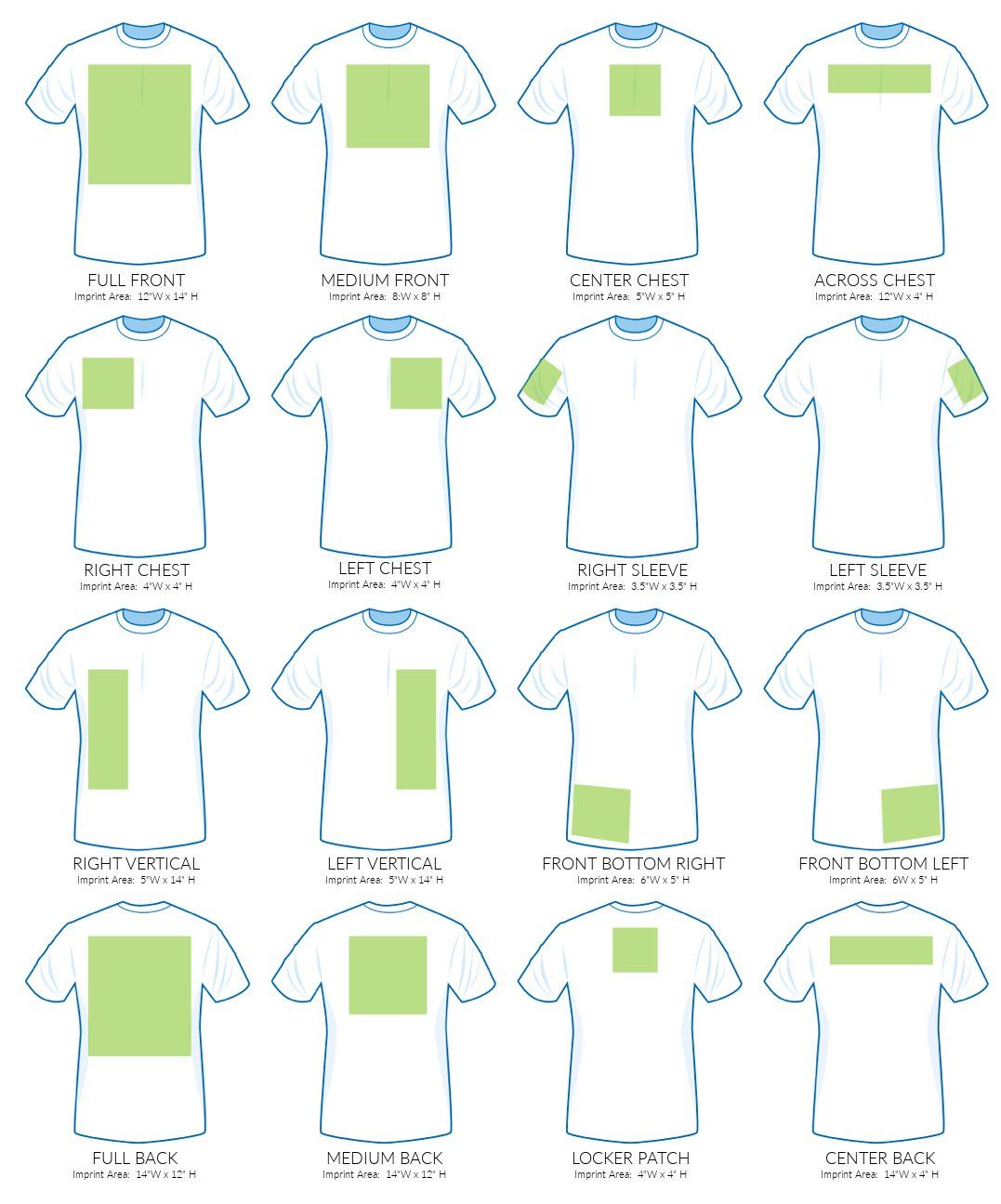

PRINT LOCATIONS

Frequently Asked Questions

ARTWORK REQUIREMENTS

Frequently Asked Questions

RASTER FILES

File extensions: AI or EPS. SVGs work sometimes but results vary.

- Requirements: Convert all fonts to outlines.

- Does not contain embedded raster images

VECTOR FILES

File extensions: PSD, JPG, PNG, TIF.

- Requirements:Artwork is same as print size in inches

- 300 DPI

HOW TO SIZE YOUR LOGO

Frequently Asked Questions

File extensions: AI or EPS. SVGs work sometimes but results vary.

- Requirements: Convert all fonts to outlines.

- Does not contain embedded raster images

Frequently Asked Questions

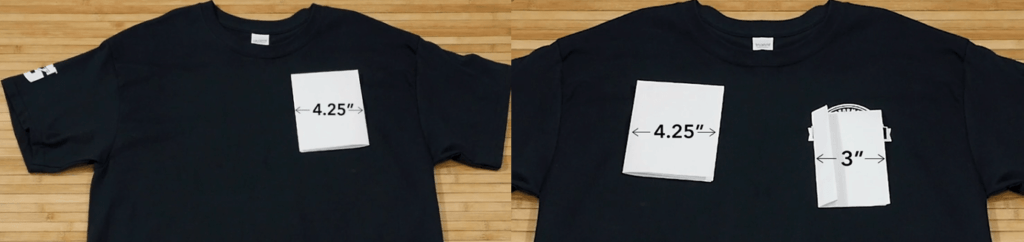

If you want a nice, big graphic, 11 to 13 inches is typically the size of what you’ll print on the shirt, depending on the size of your shirt. The longest side of a sheet of paper is 11 inches long, giving you a nice visual representation of how large your graphic may look on a shirt.

Frequently Asked Questions

If you line up the short side of the piece of paper, you’ll get a good approximation of how your eight and a half inch wide print will look like after we print it on your shirt.

Frequently Asked Questions

An easy way to visualize a small front logo is by folding the long side of a paper in half. This gives you a good approximation of how a smaller, centered logo will look like when it’s printed on a shirt.

Frequently Asked Questions

Typically, a good size for a chest print is between 3 and 4 inches wide. If you the wide end of the sheet of paper in half again, you get a 4.25” space, giving you a good visualization of how large your 4” graphic can look. If you fold it in by around an inch, you can compare the 4” with the 3” size to see which works best for you.

Frequently Asked Questions

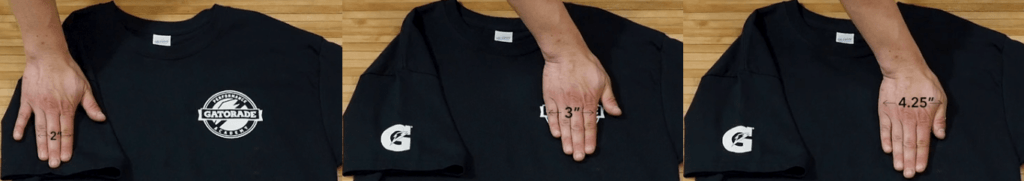

If you’re considering a screen printed sleeve graphic, the rule of thumb is around 2 inches wide. By folding your 4.25 inch sheet in half, you’ll have a sheet around 2 inches wide. That’s the exact size of the print we have on this sleeve.

Frequently Asked Questions

One other way that screen printers approximate measurements is by using their hands. Placing three fingers down on a shirt is around the size of a sleeve print, or two inches wide. Placing four fingers down will give you a width of around 3 inches and five fingers will be around 4 inches, giving you the rough size of a chest print.

CHOOSING THE RIGHT SHIRT

Frequently Asked Questions

When you start your project, B2B Signs and Prints can recommend thousands of shirts for you. Choosing a shirt to print on is the same as buying anything online. There’s a myriad of options, each with their own unique quality and feel. After you submit a quote request, B2B Signs and Prints will work with you to determine the goals for your project and recommend a couple of options that will work best for your project.

Frequently Asked Questions

Our team will take into consideration information such as: your budget, the desired quality and softness of your shirts, and the lifestyle of your customers in order to find you the best options for your brand. After processing your objectives, B2B Signs and Prints will send you links to products that we believe will be a good fit for your business.

Similar to shopping for anything online, your only resources before deciding the base material for your print will be pictures and product descriptions. Although these are accurate, there’s always the chance that you receive the product and it doesn’t fit how you expected it, or it doesn’t feel like how you hoped it would.

Frequently Asked Questions

To help you save time and money, B2B Signs and Prints can help you sample the shirts you’re interested in prior to deciding the base material for your project. Our customers are welcome to come and visit B2B Signs and Prints display rack in order to feel and try multiple products in person. If you’d like to try a product that we don’t have among our samples, we can order a sample at essentially no cost.

Frequently Asked Questions

When a customer finds a shirt they like, they can either drop by our office to try multiple styles, or they can request a sample. After requesting a sample, B2B Signs and Prints can send our customers a blank sample shirt for a customer to evaluate the feel and fit. Although there’s a charge for the shirt, if a customer chooses to move forward with a larger job, B2B Signs and Prints will credit the cost of the sample in the job, essentially giving you a free sample shirt.

CUSTOMER SUPPLIED GARMENTS

Frequently Asked Questions

See detailed information below. Note: fees may apply for unlabeled shipments, mixed shipments, or difficult to process shipments.

1. Submit your garments for inspection

2. Garments are approved for production

3. Send a complete and accurate accounting of the garments to be printed to B2B Signs and Prints customer service

4. Ship / deliver garments to B2B Signs and Prints, labeled with your name, invoice number, or PO number

Frequently Asked Questions

All customer supplied garments must be reviewed and approved by a manager before we accept them for printing. For known garment manufacturers and brands, the garment manufacturer and style number or a link to the garment is sufficient.

Frequently Asked Questions

If garments are of unknown origin or if we have questions about the garments, then they must be inspected in person before we accept the job for product. We reserve the right to reject any garments for production. We look at the following criteria when inspecting garments prior to production.

- Are there multiple types of garment styles or materials? Inspect all.

- What material is the garment made of out?

Is the garment camouflage or other dyes that like to migrate?

- Does the garment stretch?

- Is the garment ribbed?

Can the requested decoration type be applied to this garment?

- Is customer requesting to print over the seams?

- How many layers does the garment have? 1 or 2?

- Will the print fit onto all of the requested garments?

- Will the garment fit onto the necessary platen?

- How expensive is the garment?

Frequently Asked Questions

All jobs with supplied garments carry a 5% allowable defect rate. That means that up to 5% of your order may be damaged, destroyed, lost or for any reason whatsoever not returned to you.

Frequently Asked Questions

Customer supplied garments must be shipped or delivered to us in the following manner. Failure to do so may result in fees or delays to your order:

1. Send your customer service representative a complete and accurate accounting of the garments to be shipped to B2B Signs and Prints. This is as simple as sending us the invoice from your vendor.

2. Garments must be shipped to us with your name and company name, the Printavo invoice number or your PO number clearly labeled on the carton(s). If you are using a PO number, you must supply the customer service person with your PO and ensure that it is listed on your work order.

3. Garments for multiple invoices or POs must be separated into separately labeled cartons. Do not mix orders into the same cartons.

4. Garments must be provided to us unbagged

Frequently Asked Questions

Your Name / Company Name + PO 12345

B2B Signs and Prints

1785 Timothy Drive, Suite 5, San Leandro, CA 94577

Frequently Asked Questions

1. Unmarked shipments create delays in the production process

2. Orders received without proper tracking information creates additional overhead on receiving and office staff

3. Bagged garments require additional time to process for our receiving staff

Frequently Asked Questions

1. Failure to send us accurate counts or mark your orders correctly will result in a charge of $25 per order

2. We do not adjust the cost down for if there is a shortage on your order and you supply us with incorrect counts

3. Bagged garments carry a charge of $.25 per garment for unbagging